Reliable servicing by experienced engineers

Keep your pumps, fans and critical components performing with specialist support from Salvtech. We work across the UK’s most demanding industrial sectors, offering tailored, expert-led servicing that helps prevent breakdowns, reduce vibration and extend equipment life, without causing disruption to your operations.

Industry-specific knowledge, not generic fixes

We’re not a general maintenance firm. Our team specialises in servicing pumps and fans for Energy-from-Waste, Paper, Tissue, and Process industries. Every service is tailored to your environment, operational pressures and performance standards.

-

In-house pump repair and servicing

We restore worn pumps to optimum performance using skilled workmanship and high-quality parts. Whether centrifugal or progressive cavity, we focus on reliability, flow accuracy and extending life cycle, all backed by expert diagnostics.

-

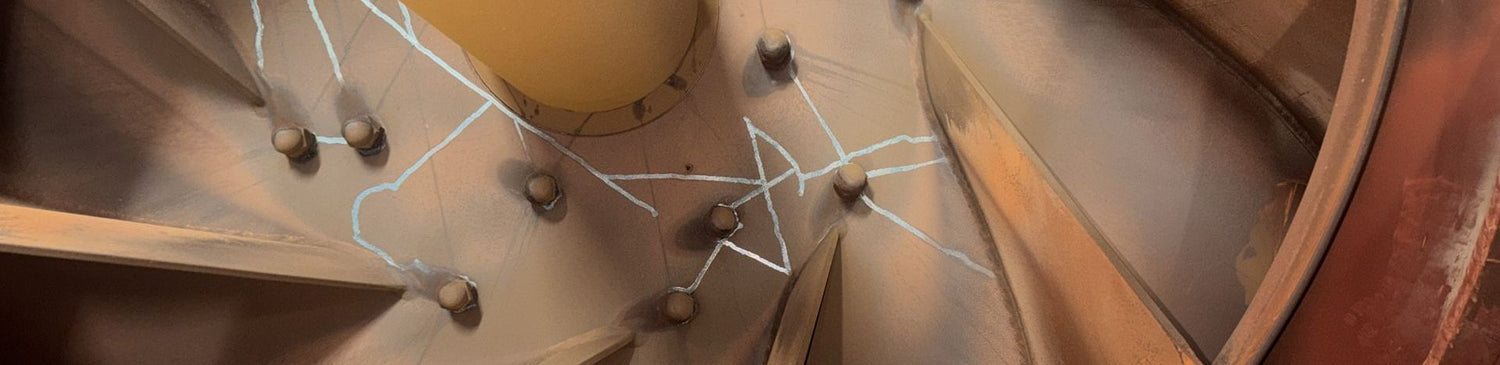

Crack detection to prevent failure

Using dye penetrant testing, we detect surface flaws in impellers that could otherwise cause catastrophic failure. Our crack detection service ensures plant safety and improves reliability during critical outage windows.

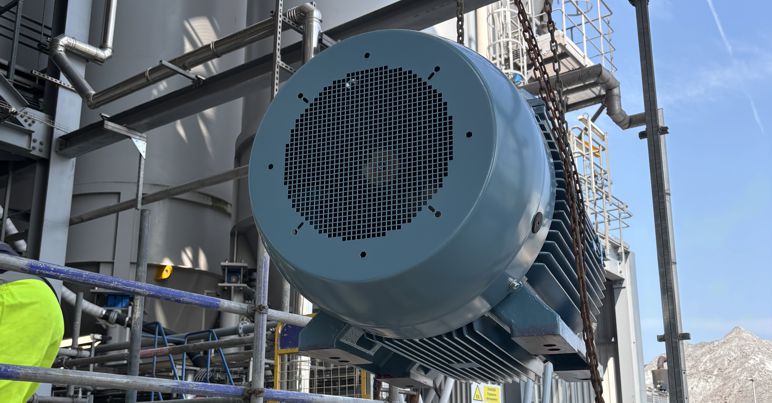

Full annual outage support for EfW

Our engineers manage complete fan outage services for EfW plants, from impeller changes to ACC fan overhauls. We improve safety, reliability and performance, whether you’re running ID, FGR, or primary/secondary air fans.

Vibration, balancing, and laser alignment

We combine in-situ and in-house balancing, vibration analysis and laser alignment to reduce wear, spot developing faults and avoid unplanned failures. Services include instant reporting, Bluetooth sensors and remote monitoring for real-time insights.

Specialist support for Paper and Tissue mills

We carry out detailed screen basket inspections for paper mills using precision tools and proactive maintenance planning. Our expert-led reports guide re-chroming decisions and keep your screening systems running reliably.

“A system is only as strong as its weakest link.”

Do you provide full outage support for EfW fans?

Do you provide full outage support for EfW fans?

Yes. We specialise in outage services for Energy-from-Waste plants, including bearing, casing, impeller and shaft changes. We work on ID fans, FGR fans, and ACC units - offering modifications to improve long-term maintenance safety and operational performance.

Do your engineers hold any safety qualification?

Do your engineers hold any safety qualification?

Yes. Our engineers are trained to SSSTS Site Supervisor level as a minimum and hold many certificates from Confined Space, Grinding Wheels, Overhead Cranes, Lifting and Slinging and any other safety training and certification needed for our work. Our Engineers are trained, competent and experienced in site work and we treat the safety of people as our Number 1 priority.

Can you service fans and pumps from different manufacturers?

Can you service fans and pumps from different manufacturers?

Absolutely. We repair and service fans from all suppliers and centrifugal and progressive cavity pumps from brands like Sulzer, Ahlstrom, Warman, Seepex, Allweiler, Netzsch, and L&M. Whether OEM or non-OEM, we ensure fans and pumps are restored to specification using high-quality components.

How do you minimise vibration and misalignment issues?

How do you minimise vibration and misalignment issues?

We combine in-house and on-site impeller balancing with precision laser alignment and vibration analysis. Our Bluetooth-enabled Phantom system allows remote monitoring and real-time diagnostics - reducing failure risk and extending equipment life.

What kind of fault detection do you offer?

What kind of fault detection do you offer?

We use dye penetrant crack detection during outages to identify surface-level faults in impellers. Combined with vibration analysis and wear inspections, this allows early detection of failures before they impact production or safety.

Do you inspect screen baskets for paper mills?

Do you inspect screen baskets for paper mills?

Yes. Our screen basket inspection service includes wear assessment, profile checks and rechroming recommendations. We use precise measurement tools from AFT and industry-specific experience to ensure your mill’s screening systems run reliably and efficiently.