Reliable pump systems that deliver results

We supply high-quality centrifugal, positive displacement and slurry pumps tailored to tough industrial environments. From pulp and wastewater to food production and energy recovery, our solutions are engineered for reliability, efficiency and long-term value, backed by expert support and rapid access to spares, servicing and technical guidance.

Pumps for tough industrial demands

Our pumps handle complex fluids, from fibrous pulp and high-viscosity sludge to hygienic food products. Whether you need corrosion resistance, CIP compatibility, or abrasion-proof designs, we’ll specify a solution that meets your exact process needs.

-

Tailored selection, no guesswork required

Choosing the wrong pump costs time and money. We help specify the right solution using sector expertise and in-house tools. We’ll advise on impellers, seal types, NPSH, BEP, power use and system

compatibility, so you get it right first time. -

Spares and backup, always available

Avoid downtime with fast access to high-quality OEM and non-OEM spares. Whether you need single parts or complete drop-in units, we keep stock on hand and can source over 100,000 components through our Lotzer & Mühlenbruch partnership.

Servicing to maintain long-term performance

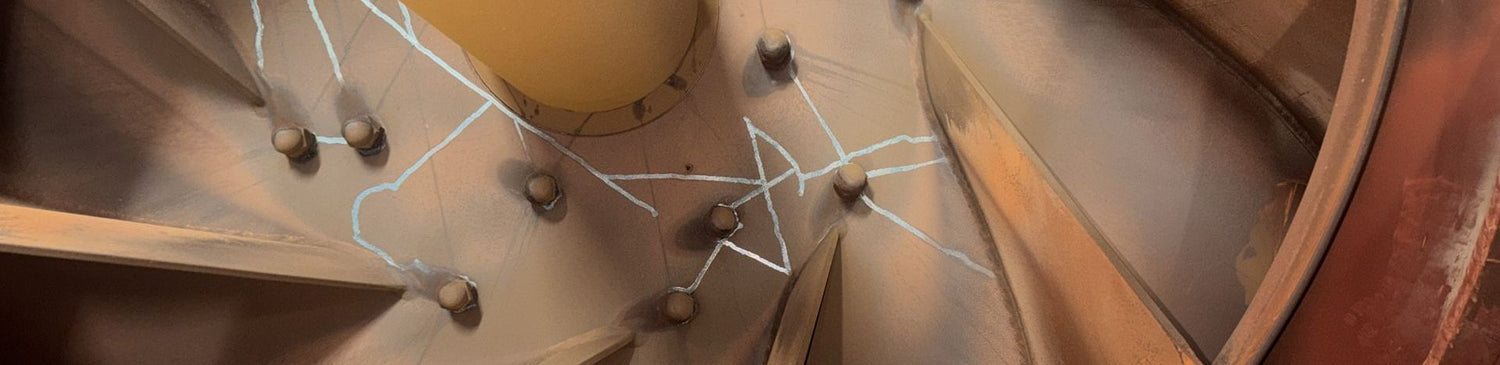

We offer pump servicing in our workshop or on site. With vibration analysis, crack detection and precision balancing, we help prevent failures, extend pump life and reduce long-term maintenance costs across every sector.

Refurbishment and exchange options

Extend pump life with our cost-effective refurbishment service. For urgent jobs, our exchange programme lets you swap in a reconditioned unit while your original is being rebuilt, minimising downtime and restoring performance fast.

“Balance isn’t optional - it’s essential.”

How do I know which pump is right for my application?

How do I know which pump is right for my application?

We help you specify the right pump based on fluid type, viscosity, flow rate, pressure, temperature and solids content. Using in-house tools, we provide guidance on impeller types, NPSH, BEP and energy efficiency to ensure optimal performance and system integration.

Can you supply pumps for abrasive or corrosive media?

Can you supply pumps for abrasive or corrosive media?

Yes. We offer armour-plated and corrosion-resistant pumps such as the LMW-ONE and LMS-DF series. These are ideal for sludges, seawater and chemical applications. Material options include duplex stainless steel, SEBF coatings and ceramic-lined internals.

Do you provide hygienic pumps for food and pharma?

Do you provide hygienic pumps for food and pharma?

Absolutely. We supply stainless steel positive displacement pumps like the LM-HS CIP and rotary lobe HCL series. These are designed for clean-in-place (CIP) systems and gentle product handling - meeting strict hygiene standards for food, beverage and pharmaceutical sectors.

Do you provide pumps for potable water as well as wastewater?

Do you provide pumps for potable water as well as wastewater?

Yes. We supply pumps for all water applications including effluent treatment and fresh water systems. We use pumps manufactured from Stainless steel like the CHRMU, HyClean and and rotary lobe HCL-B series.

What if my pump fails, how quickly can you respond?

What if my pump fails, how quickly can you respond?

We offer fast turnaround through UK-held stock, workshop servicing and a pump exchange programme. If needed, we can provide reconditioned units while your pump is refurbished - minimising downtime and avoiding production delays.

Do you support legacy or uncommon pump models?

Do you support legacy or uncommon pump models?

Yes. With access to L&M’s modular range and a large stock of spares, we support legacy centrifugal and positive displacement pumps. We can also identify compatible parts using OEM references, technical specs, or physical inspection.