Efficient, sustainable bottom ash management

Salvtech supplies and supports Magaldi’s dry bottom ash systems for Energy-from-Waste plants. These technologies reduce environmental risk, recover valuable materials and eliminate the need for water in ash handling, creating a smarter, safer and more sustainable alternative to traditional wet systems.

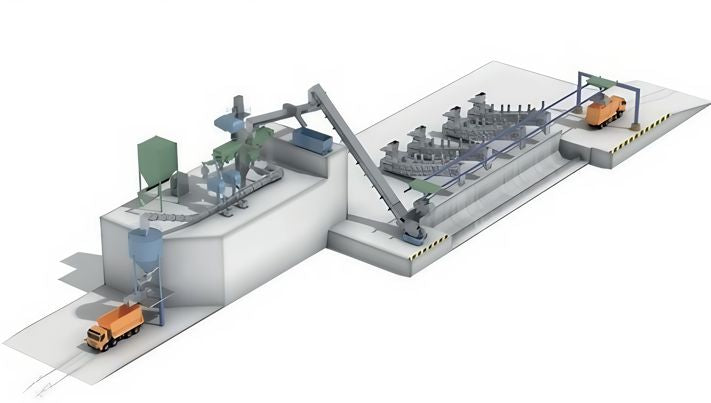

ECOBELT® Waste Ash – Dry IBA Handling

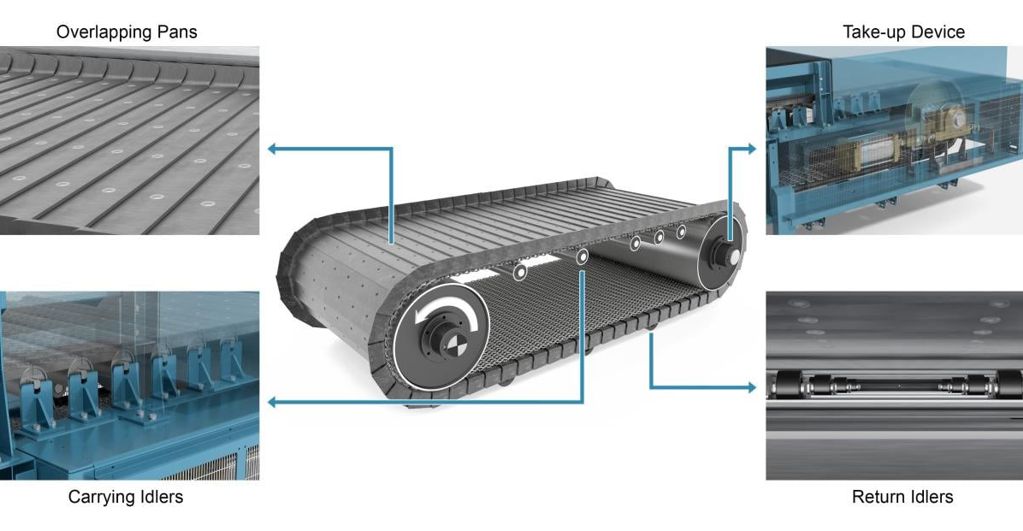

The ECOBELT® system extracts bottom ash dry, directly from the combustion chamber. It eliminates water use and captures unburnt residues through post-combustion, delivering TOC levels typically below 0.5%. Clean, dry ash means better metal recovery, sealed dust-free transport and safer long-term operation.

-

MADAM – Magaldi Dry Ash Management

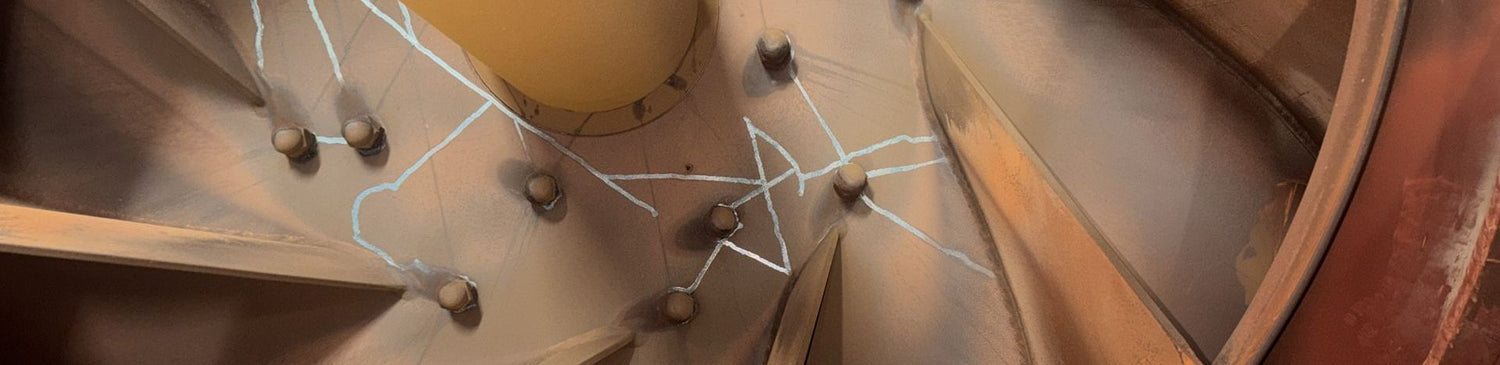

MADAM conditions and stabilises dry ash into a usable material. This proprietary agglomeration process improves flow, eliminates the need for maturation and simplifies storage and transport. Metals are immediately recoverable and aggregates can be reused or sold, delivering direct value from waste.

-

Lower water use, higher material recovery

Magaldi’s dry IBA systems consume zero process water and eliminate water contamination risks. The preserved condition of the ash allows for higher recovery rates and improved safety in post-treatment handling, with reduced operating and maintenance costs over time.

Ideal for new builds and retrofits

ECOBELT® and MADAM are suitable for both new EfW installations and retrofit projects. They require minimal disruption during installation, integrate with existing systems and bring outdated plants in line with modern environmental expectations, future-proofing compliance and recovery strategies.

Fully integrated ash recovery in-house

With both technologies installed, EfW facilities can manage the complete ash recovery process on site. This reduces reliance on third-party treatment, cuts operational delays and introduces new revenue streams from the direct sale of metals and clean aggregates.

Designed for compliance and sustainability

Magaldi’s systems help EfW operators meet the strictest regulatory requirements while contributing to the circular economy. The move to dry extraction aligns with national sustainability goals and strengthens environmental credentials with stakeholders and regulators alike.

“Every connection matters.”

How does dry bottom ash handling differ from wet systems?

How does dry bottom ash handling differ from wet systems?

Dry systems like ECOBELT® extract ash without using water, avoiding contamination and reducing the need for water treatment. This allows for better preservation of metals, higher recovery rates and lower environmental impact - making it a cleaner and more cost-effective alternative.

Can these systems be retrofitted into existing EfW plants?

Can these systems be retrofitted into existing EfW plants?

Yes. Both ECOBELT® and MADAM are designed for new builds or retrofit applications. They can be installed with minimal disruption to existing operations, offering a practical upgrade path for plants still using traditional wet ash handling methods.

What kind of materials can be recovered from IBA?

What kind of materials can be recovered from IBA?

Dry handling preserves metals in a clean, dry state - making them easier to recover and sell. Aggregates produced via the MADAM system are free from water contamination and ready for immediate use in road construction and civil engineering.

Is maturation or curing still required after ash extraction?

Is maturation or curing still required after ash extraction?

No. Thanks to in-line conditioning with the MADAM system, maturation is completely eliminated. The treated ash is stabilised and ready for safe handling, storage, and commercial use - helping reduce land use and processing time.

How do these systems support environmental compliance?

How do these systems support environmental compliance?

Magaldi’s dry systems reduce water use, minimise emissions, and enhance post-combustion control. With TOC levels typically below 0.5%, they help plants meet strict environmental standards while contributing to circular economy goals and sustainability reporting.