Tailored solutions for paper mill systems

From bale handling to approach flow, we supply, install and support specialist machinery for paper and tissue mills. Working closely with AFT, Sicma and L&M, we deliver customised solutions that improve efficiency, reduce downtime and ensure seamless integration with your existing setup.

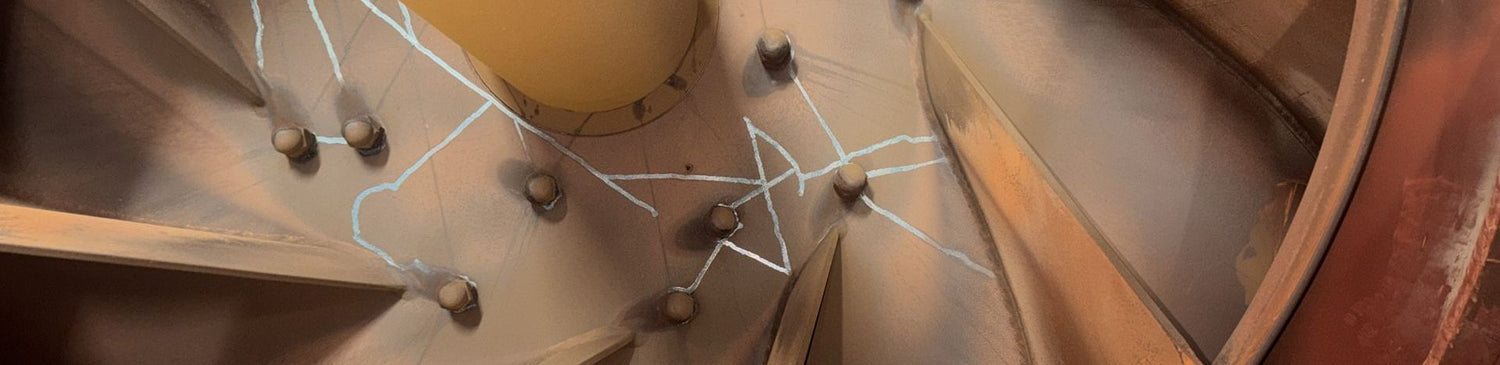

Screening and screening components

Using AFT’s leading screening systems, we offer precise separation of contraries like staples, plastics and stickies. Our equipment delivers low fibre loss, consistent product quality and easy maintenance access, ensuring round-the-clock process reliability and performance. We also supply baskets and rotors for any other OEMs screening machines.

-

Pulping and Cleaning

Our AFT pulping and cleaning systems break down bales effectively while preserving fibre quality. We focus on early contaminant removal, easy access for servicing and energy-efficient operation, ensuring cleaner pulp and less wear-related downtime.

-

Bale Handling

We supply automated bale handling systems via Sicma SpA to reduce manual input and increase productivity. Our solutions ensure consistent feeding of raw materials, effective dust and bale wire control and compatibility with different bale types, supporting safe, efficient and reliable operations.

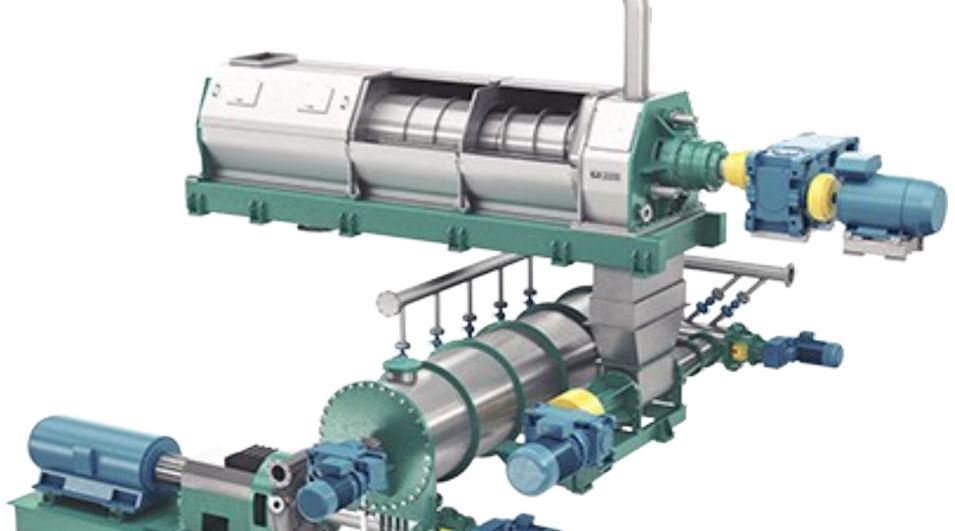

Refining and Deflaking

With AFT deflakers and refiners, we help mills optimise sheet strength without damaging fibres. Our systems offer stable performance, energy efficiency and operator control, supporting consistent output and easier, safer adjustments during production.

Dispersion Equipment

Our dispersion equipment from AFT remove visible and invisible contaminants through careful temperature and consistency control. Designed to maintain fibre integrity, these systems ensure a clean, high-quality output without compromising process efficiency.

Approach Flow

We supply AFT approach flow systems that control consistency, pressure, and air content in pulp just before it reaches the paper machine. Our solutions protect sheet formation, improve fibre orientation and ensure clean, consistent delivery to the wire.

“Maintenance is the key to longevity.”

Can you supply machinery for specific stages of the paper process?

Can you supply machinery for specific stages of the paper process?

Yes. We supply machinery for every major stock preparation and handling stage - from bale handling and pulping to screening, dispersion, approach flow and reel handling. We work with AFT, Sicma and L&M to deliver specialist solutions matched to your mill’s needs.

Do your systems integrate with existing equipment?

Do your systems integrate with existing equipment?

Absolutely. We tailor every installation to suit your current layout, pipework and control systems. Whether upgrading one stage or planning a rebuild, our team ensures seamless integration - avoiding costly retrofits or unnecessary changes.

What if we need bespoke advice for a shutdown project?

What if we need bespoke advice for a shutdown project?

We regularly support mills during shutdowns and tight project windows. Our flexible, hands-on approach means we’ll work closely with you to plan delivery, installation and commissioning - avoiding delays and ensuring a smooth restart driven by team focussed on the safety of people.

Are spare parts and servicing available after installation?

Are spare parts and servicing available after installation?

Yes. We provide wear parts and specialist servicing for all equipment we supply. We can also advise on rechroming (eg screen baskets), stock common spares and carry out inspections to help avoid unplanned failures and downtime.

What makes your systems better than standard OEM packages?

What makes your systems better than standard OEM packages?

Many OEMs offer one-size-fits-all solutions. We take a different approach - offering bespoke advice, close project support and access to world-leading technology from our agency partners. You get the flexibility of an SME with the backing of global manufacturers.