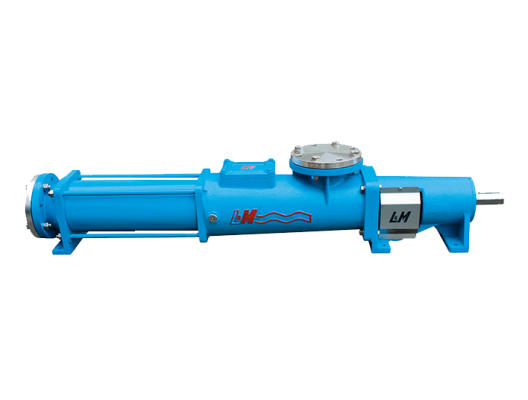

Eccentric Screw Pump

The LMHS pump series has been designed in order to get a positive displacement pump with a helical rotor to decant viscous liquids, with or without solids in suspension; being suitable for the waste water, chemical, cosmetic, pharmaceutical and food industries, as well as many others.

These pumps were designed and manufactured in order to enable the possibility to change from a closed coupled pump to one with a pedestal bearing, while maintaining the use of the same pump casing. This simple and economical solution has allowed for the manufacturing of the compact closed coupled units which are even easily installed into narrow environments.

The LMHS pump is positive displacement, self-priming pump with only one rotating rotor and fixed stator. The steel rotor is a single threaded screw which, rotating inside the rubber stator vulcanised inside a steel pipe, pushes the pumped fluid from the suction to the discharge outlet through moveable chambers being created by the movement. The pumped fluid thus passes through the pump without any lamination, centrifugation or meshing of the product.

Characteristics:

The L&M LMHS pump, is a self-priming screw pump. For the use of liquids such as water, at 20 C, it is able to prime a 7 metre column, even at low speed. The flow rate available is obtained by taking into account certain data: eccentricity, diameter of the rotor, speed and pitch. The discharge pressure is independent of pump speed and only depends upon the number of stages.

Applications:

The LMS HS can be used for a wide range of high and low viscosities, up to 800,000 Cps. These pumps can also pump products that contain solids in suspension, as well as highly abrasive mediums, by modifying the diameter of the rotor. A remarkable reduction of the wear on the stator and rotor can be obtained by decreasing the speed of the rotor.

Handling:

While the pump is easy to operate, it is recommended to note the following to ensure high-efficiency and long lifetime:

- The pump is self-priming, however it is advised to fill the pump casing with fluid to be pumped prior to start up.

- Ensure that the suction pipe has a suitable diameter

- Never run the pump dry, otherwise the stator may burn

- Adjust the pump flow by regulating the number of revolutions and avoid throttling the discharge port, because the pump could vibrate.

The simple, functional and modern design of the LMHS pump, allows a change from a compact-block mounted pump to a pedestal bearing house variation. All pumps in this range can be supplied horizontally or vertically, on a base or on a trolley.

Pump Sizes:

1 stage – up to 6 bar

2 stages – up to 12 bar

3 stages - up to 18 bar

4 stages – up to 24 bar