The Krima Refiner is designed for high consistency treatment, with the best results being reached when the inlet consistency is between 20 and 35%. The technically superior, and patented, infeed zone allows treatment of all types of fibres without the risk of blocking. The infeed zone also contributes to a very low energy consumption of the unit. The Refining provides a high pumping effect which feeds the pulp directly to the required station, i.e. machine vat or storage tower.

In order to achieve maximum pumping effect, the rotor can be equipped with special pump flights. An outlet consistency of up to 15% can be reached in the standard refining housing. High consistency outlet can be reached by using a HC refining house configuration.

Description

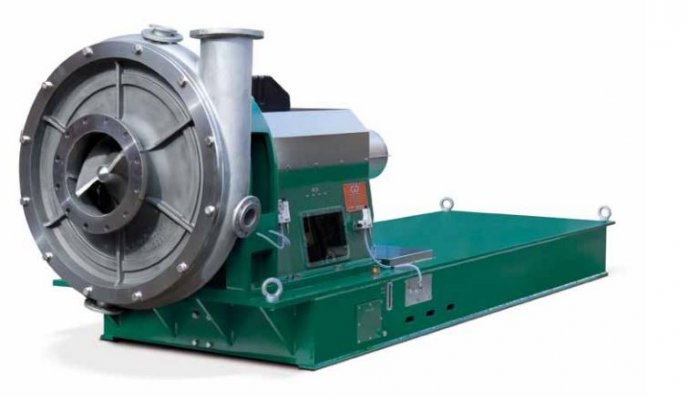

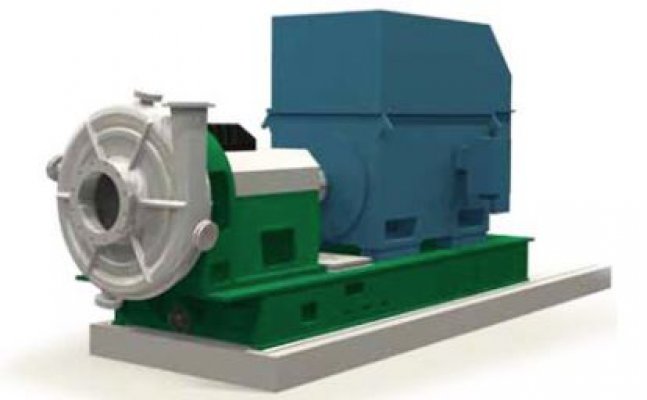

The Krima Refiner is mounted on a baseplate on which the main motor is also situated. This arrangement allows a perfect alignment between the refiner and the motor shaft. All parts in contact with the pulp are manufactured in acid-proof steel. All other parts are sandblasted and coated with an epoxy-paint. The protective covers for the coupling and lubrication system are manufactured in polished stainless plate. The inspection openings are covered with plexiglass.

Features & Benefits

- Optimum performance

- Low energy consumption

- Different refining discs

- Easy maintenance

- Many different applications such as pulp, rejects etc

- Discharge consistency 3 - 35%

- Capacity range 10 - 600 TPD